LED light pole screens are becoming increasingly popular in seaside areas for urban lighting and information display. Their high brightness and energy-saving characteristics make them ideal for these environments. However, the seaside presents unique challenges, especially concerning salt spray and high salinity. This article outlines essential precautions to ensure the stable and long-term operation of LED pole screens in coastal settings.

Salt spray is a common issue in coastal environments. Sea breezes carry salt particles onto land, where they can accumulate on various surfaces. For LED light pole screens, salt spray can lead to significant problems:

Rusting of Metal Parts: Salt accelerates corrosion, which can damage the metal components of the LED screens.

Damp Circuit Boards: Moisture from salt spray can affect the internal electronics, leading to malfunctions.

Short Circuits: If salt spray infiltrates the circuit board, it can cause short circuits, disrupting normal operation.

To ensure the reliability of LED pole screens, it’s crucial to select models with high salt spray resistance.

One of the primary considerations for LED light pole screens in seaside applications is the material used in their construction. The outer shell and supporting structure must resist corrosion effectively. Here are some recommended materials:

Anodized Aluminum Alloy: This material offers excellent corrosion protection and is suitable for both light poles and screen frames. Its anodized finish helps to prevent salt from contacting the underlying metal.

High-Quality Anti-Corrosion Coatings: Using specialized coatings can effectively isolate salt and moisture from metal surfaces, extending the life of the equipment.

Selecting corrosion-resistant materials will help mitigate the adverse effects of salt spray and enhance the durability of LED light pole screen.

Waterproofing is vital for LED light pole screens used in coastal areas. Proper sealing will protect the internal components from moisture and salt spray. Consider the following recommendations:

Well-Sealed Joints: Ensure that all seams and interfaces of the screen are tightly sealed. This prevents salt and moisture from infiltrating the device.

Rubber Gaskets and Waterproof Glue: Use high-quality gaskets and waterproof adhesives to reinforce the sealing of the screen. These materials effectively block moisture and salt from entering the unit.

A robust waterproofing design is essential for maintaining the functionality and longevity of light pole screens in seaside conditions.

When choosing pole LED screens, prioritize products that have undergone rigorous salt spray resistance testing. Look for manufacturers that provide:

Test Reports: Reliable documentation confirming the product’s performance in salt spray conditions.

Certifications: Relevant industry certifications ensuring that the equipment meets high standards for durability and performance.

Additionally, consider the specific environmental conditions of the seaside, such as high temperatures and humidity. Choosing products designed for these factors will enhance their reliability.

Regular maintenance is key to prolonging the lifespan of LED light pole screens in coastal environments. Here are some maintenance tips:

Routine Inspections: Schedule periodic checks to identify signs of corrosion or damage. Early detection can prevent significant issues.

Cleaning: Regularly clean the screens to remove salt deposits and other debris. This practice helps maintain visibility and prevents corrosion.

Component Checks: Inspect and, if necessary, replace any worn or damaged parts to ensure optimal performance.

By committing to regular maintenance, you can effectively combat the challenges posed by salt spray and ensure the reliable operation of pole LED screens.

LED light pole screens offer many benefits for urban lighting and information display in seaside areas. However, they must contend with unique environmental challenges, particularly salt spray. To ensure stable and long-lasting performance, focus on the following precautions:

By addressing these key areas, you can extend the lifespan of LED light pole screen and enhance the overall reliability of urban infrastructure in coastal environments. These precautions not only improve the performance of pole LED screens but also contribute to a more efficient and effective urban landscape.

If you need an LED solution, you can contact us!

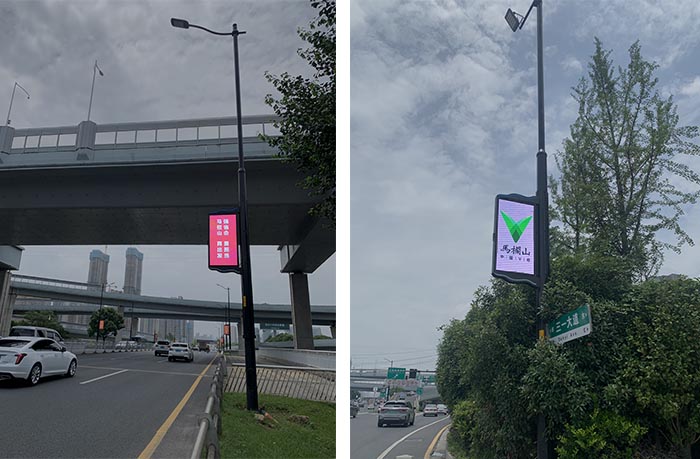

The pictures in the article are all our cases

contact us

Stay up-to-date with our new product releases and latest news articles. DECENT Technology is a leading global supplier of LED display screens, providing customers worldwide with comprehensive solutions for the research and development, manufacturing, engineering installation, and after-sales service of high-end LED display equipment and display control systems. At present, it has developed into a national high-tech enterprise with over 1300 employees and more than 400 authorized national patents. The company has successively obtained safety production license, steel structure construction qualification, system integration qualification, third level professional contracting for building mechanical and electrical installation engineering, and second level professional contracting for electronic and intelligent engineering.

DECENT Technology is positioned as "core technology oriented" and has deeply cultivated and worked in the LED industry. It has established numerous marketing centers, offices, and after-sales service outlets worldwide. The company's products are distributed in more than 200 countries and regions, and has accumulated over 40000 classic cases. The strong comprehensive strength has made DECENT Technology the preferred brand among the Fortune Global 500 companies such as Sinopec, PetroChina, Tencent, Alibaba, Huawei, and Abbott.

Since its establishment, DECENT Technology has accumulated 10 industry-leading technologies and 43 innovative "black technology" technologies; And we have developed six product lines, including professional display, universal display, conference display, commercial display, outdoor led display, and rental display, which are applied in multiple scenarios such as command and monitoring, commercial display retail, broadcasting and broadcasting, outdoor advertising, sports events, and stage performances. The product quality maintains a leading position in the industry.

In the future, DECENT Technology will continue to adhere to the business philosophy of "product+service" and the corporate values of "innovation, sunshine, struggle, and gratitude", continuously moving towards higher technology, better services, and harder quality, committed to providing professional LED display system solutions for every customer.

DECENT Technology is a leading global supplier of LED display screens, providing customers worldwide with comprehensive solutions for the research and development, manufacturing, engineering installation, and after-sales service of high-end LED display equipment and display control systems. At present, it has developed into a national high-tech enterprise with over 1300 employees and more than 400 authorized national patents. The company has successively obtained safety production license, steel structure construction qualification, system integration qualification, third level professional contracting for building mechanical and electrical installation engineering, and second level professional contracting for electronic and intelligent engineering.

DECENT Technology is positioned as "core technology oriented" and has deeply cultivated and worked in the LED industry. It has established numerous marketing centers, offices, and after-sales service outlets worldwide. The company's products are distributed in more than 200 countries and regions, and has accumulated over 40000 classic cases. The strong comprehensive strength has made DECENT Technology the preferred brand among the Fortune Global 500 companies such as Sinopec, PetroChina, Tencent, Alibaba, Huawei, and Abbott.

Since its establishment, DECENT Technology has accumulated 10 industry-leading technologies and 43 innovative "black technology" technologies; And we have developed six product lines, including professional display, universal display, conference display, commercial display, outdoor led display, and rental display, which are applied in multiple scenarios such as command and monitoring, commercial display retail, broadcasting and broadcasting, outdoor advertising, sports events, and stage performances. The product quality maintains a leading position in the industry.

In the future, DECENT Technology will continue to adhere to the business philosophy of "product+service" and the corporate values of "innovation, sunshine, struggle, and gratitude", continuously moving towards higher technology, better services, and harder quality, committed to providing professional LED display system solutions for every customer. Do you have any questions or requests?

Click below, we are happy to provide assistance. contact us